Developing a Safe Lock Out Procedure

How to Safely Lock Out / Tag Out Equipment

Lockout / tag out or LOTO is a safe isolation procedure that ensures construction equipment, machinery and power sources are properly shut down before any maintenance or repair work takes place.

By using simple padlocks and paper safety tags, along with a robust and clear permission system, the equipment can be confidently marked as safe or unsafe while repairs or maintenance are taking place.

Having safe LOTO and isolation processes on site helps to ensure that an accident does not occur when machines require service or attention.

Safe Lock Out Procedure Checklist

Safe Lock Out Procedure Checklist

Whenever a machine, electrical device or powered equipment needs maintenance, it must be safely powered down and tagged out of service. This is to ensure that other workers do not accidentally switch on the equipment when it is mid-service, when it requires repair, or when items such as guards may have been removed for cleaning and inspection.

Use the points below to help you develop your own lockout and tag out procedures.

- Make sure your team is aware that equipment is going to be serviced or locked out

- Identify energy sources to the equipment, noting that there can often be multiple sources such as electrical power, hydraulics, and pneumatic lines.

- De-energise these sources and isolate the equipment.

- Ensure the surrounding area is safe to enter and work in, removing any loose or unnecessary trip hazards or safety risks.

- Lock out and tag out the equipment and again ensure that employees are aware of the shut down.

- Conduct the service or maintenance only after vertifying that the machine is shut off and no remaining energy sources are active.

- Replace guards and panels are ensure all tools are removed from the machine.

- Power up the equipment when you are done.

- Ensure that you remove the locks and tags as per your procedures and local safety regulations.

- Let your team know that the machine is back in operation.

Always ensure you get advice from your workplace health and safety representative, the governing safety body in your area, and seek advice from the equipment manufacturer if necessary. WorkSafe Victoria has some LOTO information available online, or check with your local safety authority.

Why do you need a LOTO process?

Why do you need a LOTO process?

A clear and easy to trace LOTO process is an important part of your WHS procedures on site. Processes and documentation should identify the key responsibilities for people who are authorised to lock or tag out equipment, the chain of command for isolating a machine, and the process for putting it back into service.

The process usually requires any hazardous energy source, such as a hydraulic system, boiler, pressure system, compressed air line, spring under tension or electrical system to be assumed dangerous. Until it’s energy source has been positively identified, isolated, discharged and locked or tagged out.

Only then is it safe for authorised staff to service or work on broken or malfunctioning equipment.

What’s the difference between lock out and tag out?

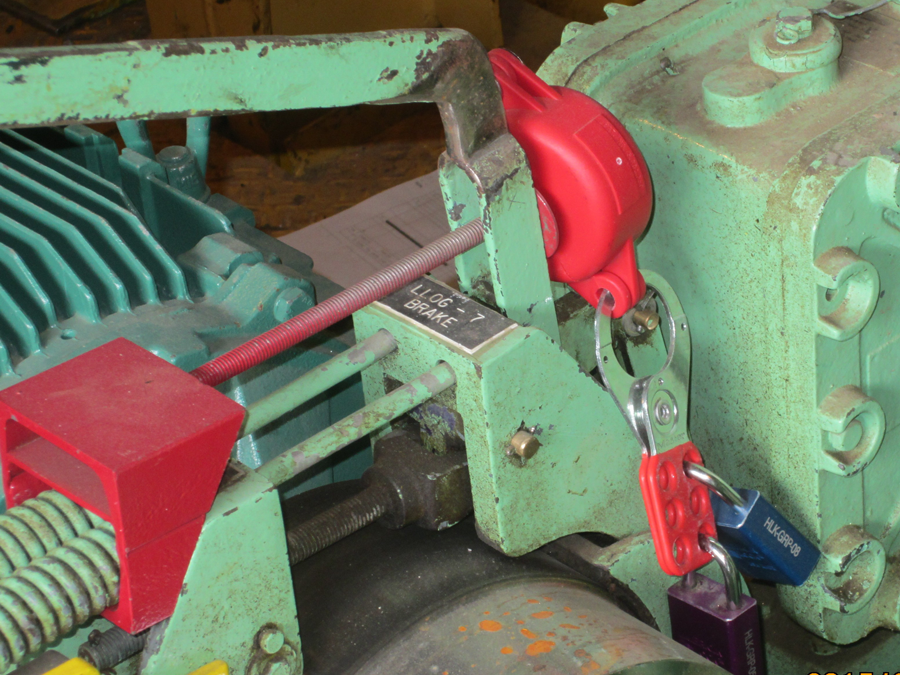

Lock out is a physical padlock placed on your plant or equipment that prevents it from being switched on. The lock is usually fixed to an access panel, on switch or control, in a safe position, to prevent the operation of the equipment. It should remain in place until it is removed by the same person who placed it there originally. This person holds on to the key or places it in a group lock box, so that only they can remove it.

Locking out equipment usually means that a permit to work on the equipment is also required. Once locked out, machinery should not be touched until the authorised person carries out the service or maintenance required.

Multiple locks can also be used by adding a hasp. This steel device has slots for many padlocks to attach, meaning that multiple workers can add their lock to the hasp. This helps to keep the chain of command in place, as all workers need to sign off on the equipment by removing their padlocks.

Tag out is when a paper Out of Service or Do Not Operate tag is placed on equipment to protect people and equipment by alerting them the equipment is faulty, broken or malfunctioning.

The equipment should not be used until the tag is removed by the person who placed it there (or the repair technician). It should only be removed once the work is complete and it is placed back into service.

What is a group lock box for?

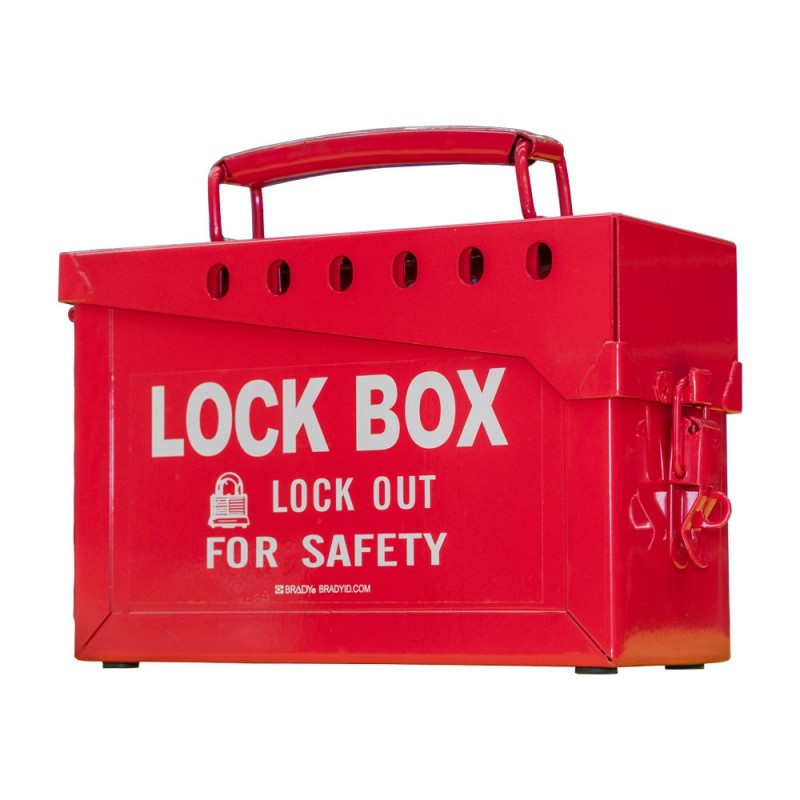

Group lockout boxes are small tins that are designed to lock away the keys of each team member’s lock. These can be useful for large equipment where multiple points of access or energising points and power switches need to be locked off.

A group lockout box has multiple holes on the outside to hold a number of padlocks. Each access point on the machine is secured with a single padlock. Workers then place their keys in the group box, then each authorised employee places their own personal padlock on to the lock box.

Once the machine is operational again, all staff remove their personal padlock from the lock box and free the keys inside.

These simple devices ensure that the keys cannot be accessed until every lock has been removed.

Shop for LOTO supplies at Jaybro

Jaybro carries a range of different lock out / tag out products including safety tags, padlocks, hasps, lockout stations and group lock boxes.

We deliver fast right across the country so whether your job is in Sydney, Melbourne, Brisbane, Perth, Adelaide, Canberra or in a regional area we can get your order shipped to site fast!

Sign In

Sign In