The best choice for Clayform

Clayform are used to separate concrete slabs from unstable soils that can exert significant pressures on structural foundations.

Biodegradable Clayform are designed to provide temporary support for concrete during curing. They are designed to break down as the product biodegrades naturally, in contrast to other Clayform materials such as foam which merely deforms under pressure.

Introducing Clayform

Clayform is a honeycomb cardboard sacrificial formwork. It is manufactured using 100% FSC Certified material. This means it is much more environmentally friendly than foam Clayform.

Developed to create space between the soil and the building’s foundation, Clayform reduces the upward force transmitted to the structure due to ground heave. The cardboard absorbs moisture from its surroundings and is eventually broken down completely, leaving behind a perfect void in the concrete construction.

It is designed for large-scale commercial and residential projects, specifically those located on reactive soil sites.

What are reactive soils?

Reactive soils occur right across Australia, particularly in the eastern states. They are generally clay based soils that swell and shrink during environmental wet and dry cycles.

In the construction sector, site soil tests use a classification scale to determine how reactive the soil is. Soils can be classed as very stable and non-reactive: these are typically sandy or rocky areas. However, at the other end of the scale, engineering tests can reveal highly reactive silt or clay soils that require special considerations during the design stages.

Because of their sensitivity to moisture, clay soils change in volume with the seasons. This results in seasonal vertical and horizontal movement of the soil. Of course, this movement needs to be taken into account in engineering calculations. The type of soil can have repercussions for a building for decades after it is built, so ensuring the foundations are sound is critical.

If reactive soils are present at your site, you will most likely use specific slab or footing designs, which often require the use of a Clayform during the pour.

How strong is Clayform?

Clayform is extremely strong and able to withstand high pressure loading. Not only does it absorb direct impact forces, but it also has the ability to support the concrete load during pouring.

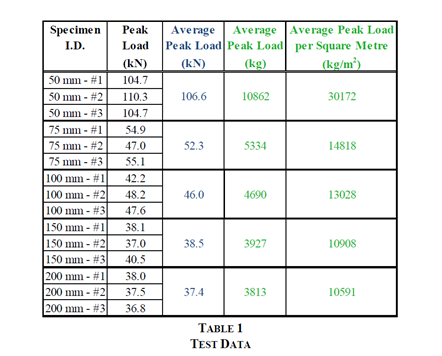

Sheets are available in thicknesses from 50 mm to 200 mm, which have been independently tested for compressive strength. During testing, the 50 mm sheet resisted an average peak load of 106.6 kN of force, equivalent to 30,172 kg of peak load per square metre. Test results for all thicknesses of Clayform are listed in the table below.

Reliable, predictable performance

Clayform is the premier void forming solution for engineers and builders. Having a genuine void under the concrete reduces the risk of the impact of the reactive soil on the structure.

Damage from soil movement and pressure placed on the slab will be reduced. Plus, the large panel format makes for quick installation on site.

Supplied unpacked, bagged individually, or bagged as a pallet,Clayform sheets are delivered to you however you choose. Bagging protects the void former sheets from moisture and premature degradation until you are ready to use them. Concrete should only be poured over void formers if they are dry and in good condition.

For more information or to get a quote, contact the Geomasta team at Jaybro.

Sign In

Sign In