How to use expansion joint foam

Many domestic and commercial projects require the installation of concrete. And where there’s concrete, there are expansion joints. The implementation of expansion joints minimises cracking in your concrete project. These joints buffer movement between adjoining sections of concrete, whether it be a driveway, garage, patio, footpath, stairway, footings, columns, or other sturdy structure.

However, you can’t simply leave a gap and let it be, that’s why we have expansion joint fillers. There are many types of fillers that can be used for expansion joints, including, but not limited to:

• Asphalt

• Fibre

• Foam

• Rubber

• Cork

Each material with its own unique benefits and features for use, but probably the most popular of the above is foam fillers.

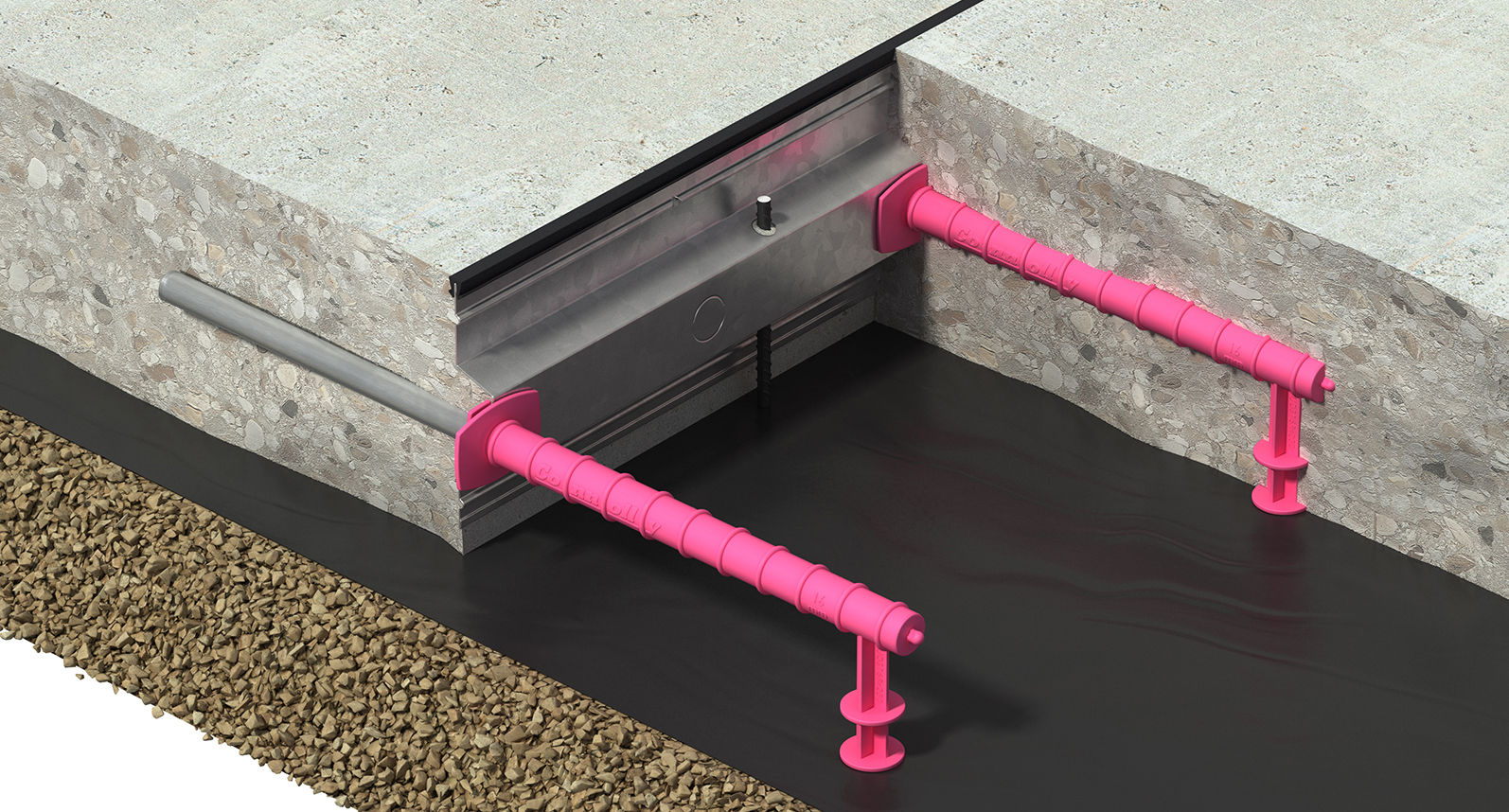

The benefit of using foam filler in your expansion joints is that it is incredibly flexible and able to be shaped around whatever design you require. This makes it perfect for filling the gaps between columns and concrete slabs, or any other application that isn’t a simple straight edge. Foam expansion joint filler is also perfect for submerged and high foot-traffic areas. It provides flexibility and strength against consistent movement and is a fast and effective way to seal gaps, preventing dust and water seepage.

Most modern expansion joint foam comes in the form of a roll of tape, making it incredibly simple to install. However, there is also Stiffjoint foam expansion joint filler. Stiffjoint comes in block form, though it is just a versatile as its tape counterpart. Available in a variety of thicknesses, you’ll find a foam expansion joint filler perfect for your project needs. These blocks, or boards, flex and hinge as required and can even be cut onsite. They are perfect for a wide range of applications including on brickwork, isolations joints and hinge joints where a compressible, low load transfer joint filler is required.

As for the tape form of expansion joint foam, here at Jaybro we supply both adhesive and non-adhesive expansion joint foam. As such, the installation process for each of these products differs, but we’re here to give you a step-by-step guide on how to use your chosen expansion joint foam.

Installing adhesive expansion joint foam tape

Adhesive expansion joint foam tape is designed to be incredibly easy to use. As indicated by its name, one side of this tape roll is adhesive which will stick to the existing structure in preparation for the pouring of new concrete.

To use this expansion joint foam, first make sure the surface to which you will be adhering the tape is clean and free of any loose particles such as dust, dirt or debris. From this point, simply begin by positioning the start of your foam tape roll at the beginning of your concrete slab and unroll to the length required. Apply firm and consistent pressure as you make your way across the concrete structure, ensuring the tape has adhered to the full width of your chosen section.

Some expansion joint foam tape will have a perforated or detachable section at the top, allowing it to be easily removed once the concrete has set. This makes room for caulking or silicone installation to seal and protect the expansion joint from dirt, liquids or chemicals.

Installing non-adhesive expansion joint foam tape

Similar to its adhesive tape counterpart, the use of expansion joint foam tape without the adhesive backing is really quite simple. The only difference being that instead of self-adhering to the existing structure, manual adhesive application is required.

Simply choose the best type of adhesive, or have a chat to your favourite Jaybro representative for an adhesive solution recommendation, and apply as required. Then, just align the start of your tape roll with the beginning of your existing slab, apply pressure and stick to the full length of the structure.

Once your chosen type of expansion joint foam has been installed, your project is ready for the concrete pour. As the new slab dries, hardens and expands, the expansion joint foam will flex, contract and mould in alignment with the shape and size of the drying/dried concrete. As time goes on and the concrete shifts, the foam expansion joint will allow the new block plenty of wiggle room, reducing cracking and keeping your project looking fresh and in tip-top shape.

Sign In

Sign In