Crash cushions and end treatments to suit concrete barriers

What are crash cushions?

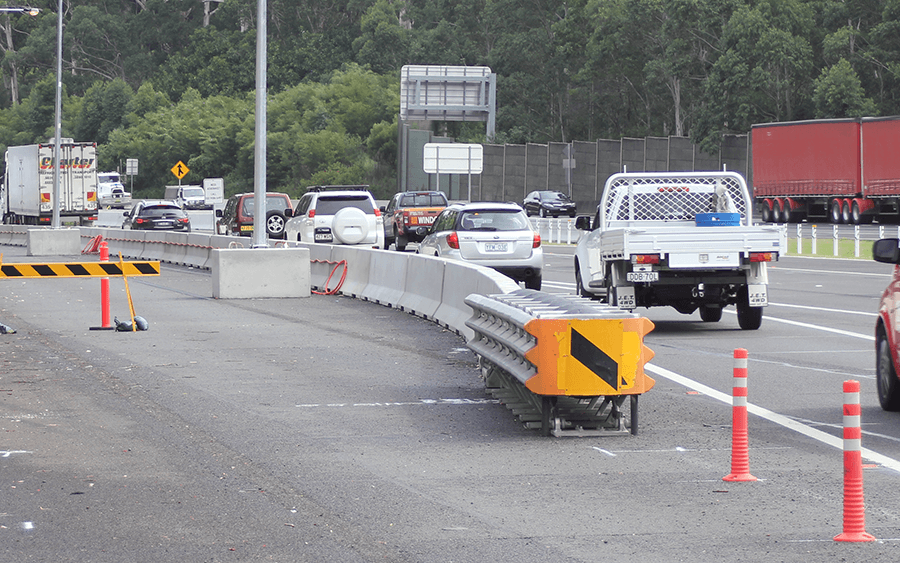

Crash cushions or impact attenuators are safety devices fixed to the end of concrete barriers and installed in front of other rigid structures such as columns, bridge supports, medians, islands and signs. Their purpose is to reduce the risk of serious injury to motorists who have lost control of their vehicle. Cars and trucks that impact a rigid road barrier head-on are at less risk of serious injury when a crash cushion is installed ahead of the barrier itself.

By absorbing the kinetic energy of an impact, crash cushions slow or redirect errant vehicles away from rigid hazards such as concrete road barriers.

These terminals are typically seen on many main roads throughout Australia as a forerunner to longitudinal road safety barriers. They allow the vehicle to be redirected in a controlled manner and dissipate some of its energy.

In addition to absorbing part of the impact of a collision, the crash cushions or terminals can also provide an anchor point for concrete barriers. Concrete barriers such as the DB80 are typically installed without ground anchoring. The modules are fixed to each other but not to the ground, therefore ensuring that they will flex as intended if impacted by a vehicle. However, most road authorities specify that concrete barriers typically need to be end anchored. A crash cushion provides the necessary fixing point.

Types of crash cushions

There are a series of different crash cushions and end treatments that are suitable for use with the Deltabloc DB80 concrete jersey barrier.

The Deltabloc DB80 is a TL-3 rated crash barrier, meaning in most circumstances, its accompanying crash cushion should be rated to the same level. The most common crash cushions are the TAU-II and the Absorb 350 as well as the Quadguard, SLED and Smart Cushion. These cushions all complement the DB80 concrete jersey barrier.

Absorb 350

The Absorb 350 is a water-filled crash cushion that is approved to the NCHRP testing levels 1 and 2. This barrier is ideal for speed zones of 70km/hr and under. It is a non-redirective, gating crash cushion.

TAU II

TAU II

The Universal TAU-II Crash Cushion is a redirective, non-gating impact attenuator. It is designed to meet the requirements of NCHRP350 test levels TL-1, TL-2 and TL-3. It uses a series of crushable cartridges to absorb energy on impact. It is constructed from a steel skeleton surrounding collapsible HDPE bays. It is typically used in speed zones in excess of 80Km/hr.

Quadguard CZ

The Quadguard is a redirective, non-gating crash cushion approved to NCHRP 350 TL-2 and TL-3. Similar to the TAU-II, it consists of a nose panel and crushable, energy absorbing cartridges surrounded by a framework of steel panels.

SLED End Terminal

This crash cushion is a narrow, water-filled non-redirective gating crash cushion that is a MASH Tested to TL-3 when used in a 4 module configuration. SLED stands for Sentry Longitudinal Energy Dissipater. It is constructed from yellow polyethylene with internal steel cables, and is designed to deform and rupture on impact.

Smart Crash Cushion Attenuator

The Smart Cushion is a fully re-directive, non-gating impact attenuator. Certain models are MASH and NCHRP 350 tested to TL-3. It differs from other crash cushions in that its collapsing motion is dependent on the vehicle's speed. It is a steel attenuator that collapses with the help of cables and rollers that slide along a track.

DB80 End treatments and transitions

DB80 End treatments and transitions

The Deltabloc range includes a sloped concrete end segment or taper that can be used if your specifications and engineering advice require the installation of an end treatment.

Additionally, specific components are required to ensure your run of Deltabloc barriers is effectively fixed to the crash cushions listed above. Each type requires a specific transition piece as laid out by Austroads guidelines, in order to ensure that it performs as expected.

Advice on concrete barrier end treatments, crash cushions and transitions

Call Ben Lorne in our concrete barrier team for detailed advice and pricing on our range of crash cushions.

Sign In

Sign In